The world housing market is currently facing a “triple crisis” that includes affordability, accessibility, and climate resilience. UN-Habitat says that around 2.8 billion people live in bad housing, and 1.1 billion of them live in slums or informal settlements. Traditional building methods aren’t closing the gap since they have problems with not enough workers, rising material costs, and a lot of carbon emissions.

As we get closer to 2025, a tech giant has come along to shake things up. 3D printing, also known as additive manufacturing (AM), is no longer only a niche experimental instrument; it is becoming a powerful force in the building sector. We are now building dignified, high-performance homes in days instead of months by stacking specialized concrete and sustainable materials with robotic accuracy.

The Speed of Innovation: 24 Hours from Idea to Bedtime

One of the most amazing changes in 3D creation is how quickly things are made. It might take weeks of planning and work by several different trades to build the structural frame and walls of a house in the traditional way. But a 3D printer works as a continuous, automated system that follows a digital CAD file with millimeter accuracy.

Recent advances have pushed these restrictions even further. The Japanese company Serendix made news lately when it printed a house in the shape of a sphere in less than 24 hours. Habitat for Humanity and Alquist 3D worked together to build a 1,200-square-foot home in Virginia. The outside walls were finished in just 28 hours, which cut the total build time by 20%.

It’s not just about making money quickly; it’s also about getting things done quickly. After a natural disaster or in places with a lot of refugees, the ability to “print” a community in a week turns humanitarian aid from temporary tents into permanent, dignified buildings.

Economic Disruption: Making it Easier to Buy a Home

There is no denying that 3D printing makes financial sense, and it is the best way to fight the housing issue. It is well known that traditional construction takes a lot of work. In a lot of places, labor makes up 50% to 80% of the total cost of a project.

This is not the case with 3D printing. For a standard 3D construction site, you only need 2 to 4 people to watch the printer. For a traditional build, you need dozens of masons and carpenters.

- Less work: Automating the process of erecting walls can cut labor costs by as much as 80%.

- Lower Overheads: Shorter construction loans and site management expenses are possible because of shorter deadlines.

- Prices that are reasonable: There are high-end custom 3D homes, but the technology has made it possible to build structural shells for as little as $10,000 to $20,000.

This means that developers can provide homes for 30% to 40% less than the average price in the area. This finally makes the “American Dream” and the world’s dream of homeownership possible for families with low incomes.

The Sustainability Edge: Building for the Planet

The building industry is one of the biggest pollutants in the world, releasing around 40% of all CO2 emissions. 3D printing is making the industry cleaner by using bio-based materials and focusing on accuracy.

Very little waste There is often a lot of wasted wood, cut-off bricks, and extra concrete on traditional construction sites. 3D printing adds layers to an object instead of taking them away. This implies that the printer only uses the exact amount of material that is shown in the digital blueprint. This can cut down on concrete waste by as much as 95%.

Materials that don’t add to carbon emissions When we look at trends for 2025, we see a transition from regular cement to “green” options. WASP and other companies are utilizing 3D printers to make homes out of dirt and agricultural waste that they get from nearby farms.

The BioHome3D project at the University of Maine, on the other hand, has printed a 600-square-foot home out of wood fibers and bio-resins, which makes it 100% recyclable.

Breaking the “Box” Mentality: Dignity Through Design

For years, “affordable housing” meant “cookie-cutter” blocks that were dull, gray, and the same over and over again. 3D printing has freed architecture from the limits of straight lines. A robot doesn’t care if a wall is straight or curved, therefore complicated shapes and organic shapes cost the same as a flat wall.

These houses are made to fit the human spirit. The world’s first 3D-printed town is in Nacajuca, Mexico. It has dwellings with built-in curving shelving, buildings that are stronger for earthquakes, and walls with a lot of thermal mass that keep the insides cool in the heat. This “Dignity by Design” method makes sure that even the cheapest homes feel special, up-to-date, and well-made.

![]()

The Titans of 2025: Taking the Lead

The market for 3D-printed building is expected to rise from about $1.6 billion in 2024 to more than $15 billion by 2032. Several important people are at the front of this effort:

- ICON (USA): They are known for their “Vulcan” printers and the huge 100-home complex in Wolf Ranch, Texas. They are even working with NASA to build things on the moon.

- COBOD (Denmark): A global supplier of gantry-based printers that have constructed the first 3D-printed buildings in Europe, Africa, and the Middle East.

- Mighty Buildings (USA): They make buildings with a special composite material that is stronger and lighter than concrete. They focus on homes that need no energy at all.

- 14Trees (Africa): A partnership that prints schools and homes in Malawi and Kenya to help close the housing gap in underdeveloped countries.

The 2025 Outlook: Getting Over the Last Hurdles

Even if technology is in charge, 2025 is a year of “recalibration.” The industry is moving out of the novelty phase and into the realities of buying things.

- Building Codes: Many areas are finally changing their rules to make 3D-printed concrete a common building material.

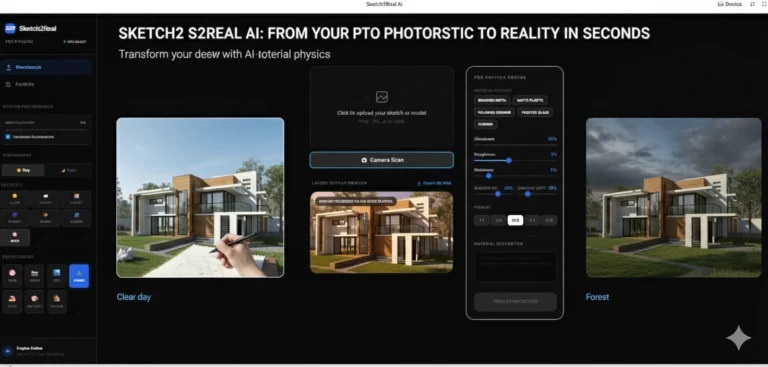

- AI Integration: AI is currently being utilized to automatically change printer settings in real time based on temperature and humidity, making sure that the structure is always optimal.

- Infrastructure Beyond Homes: There is a lot more 3D-printed infrastructure now, like pedestrian bridges, public utilities, and even “smart” urban furniture with built-in IoT sensors.

Conclusion: A New Chapter in Where People Live

The housing issue is a big problem, but 3D printing is helping us solve it. We’re not just building houses; we’re restoring dignity by combining record-breaking speed with design that focuses on people and taking care of the environment.

As the technology gets better and the global supply chain for eco-friendly “ink” grows, the 3D-printed home will go from being a viral news story to a common sight in neighborhoods. Not only is the future being built, but it is also being printed, one layer at a time.

For more blogs like this CLICK HERE!!

Reference:

Can 3D printing solve the global housing crisis? – DW – 11/17/2025