Beyond Sustainability: The End of “Take-Make-Waste”

For hundreds of years, the construction industry has worked in a straight line, almost like a “tragic” model: take materials from the ground, create something, use it for 50 years, and then either blow it up or bury it in a landfill. Even modern “green” building has typically concentrated on only being “less bad”—using a bit less water or somewhat less energy.

But in 2026, a revolution of the heart is starting. We are going beyond the “grave.” Europe is rethinking buildings through the Cradle-to-Cradle (C2C) paradigm. Instead of being finished objects, they are now seen as “material banks”—living stores of resources that will be used, recovered, and resurrected for hundreds of years.

What does “Cradle-to-Cradle” (C2C) mean?

C2C is a design philosophy that replicates nature’s cycles of growth and decay. It was created by chemist Michael Braungart and architect William McDonough. The idea of “waste” doesn’t exist in nature. For example, the flowers of a cherry tree fall to the ground and become nutrients for the soil.

C2C uses this idea in building by splitting components into two different “metabolisms”:

- Biological Nutrients: Organic materials, such as cross-laminated lumber or hempcrete, that can safely break down and go back to the earth.

- Technical Nutrients: Man-made or mineral materials (such steel, glass, and high-quality polymers) that may be reused in an endless number of industrial cycles without losing quality.

The 2026 Circular Shift’s Three Pillars

Three important pillars are changing the way construction works in Europe and making the C2C vision a reality.

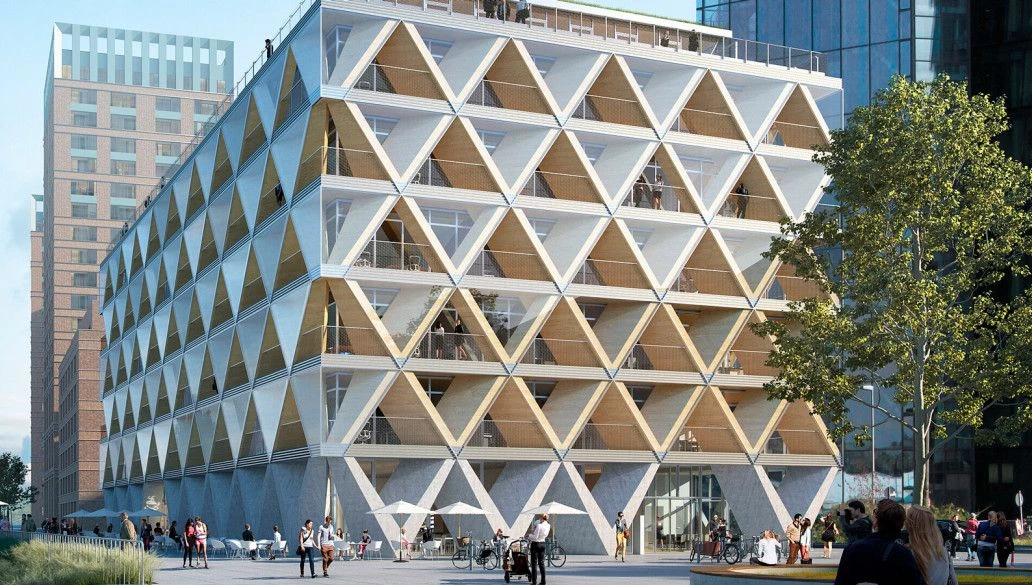

Design for Disassembly (DfD): Building with LEGO

“The glue” has always been the major problem with circularity. In traditional constructions, the materials are glued together in ways that make it impossible to take them apart without breaking them.

Design for Disassembly is now being pioneered by architects in Berlin, Amsterdam, and Milan. Instead of glue, this uses mechanical connections like bolts, snaps, and dry joints. When a building’s purpose is over, it isn’t torn down; it is “un-clicked.” Each part stays clean and ready for its next life.

Material Passports: The Building’s Digital Soul

You can’t manage what you can’t see in 2026. Material Passports are like digital ID cards for every beam, tile, and window in a structure. These passports are connected to BIM (Building Information Modeling) and have information about the health of the materials, their chemical makeup, and how to take them apart. This makes every building a clear urban mine, where the worth of resources is set from the start.

The Circular Economy Act of 2026

The movement is finally getting support from the government. The EU’s new Circular Economy Act has created a “Single Market for Secondary Raw Materials.” Using recycled or “C2C Certified” materials isn’t simply a niche choice anymore; it’s a regulatory benefit that comes with tax breaks and easier permitting.

C2C in Action: From Hamburg to Venlo

This isn’t simply a theory. The Venlo City Hall in the Netherlands is a huge material bank. Its green facade absorbs 30% of local air pollutants on a bright afternoon, and its inside is made to be completely taken apart.

New buildings in Hamburg’s HafenCity are employing C2C Certified concrete and mineral paints that don’t contain any VOCs. These structures don’t just “take up” space; they cure it by cleaning the air and water around them.

The Soulful Advantage: Our Reason for Building This Way

What makes this change “soulful” in the industry? Because it knows that buildings change how our bodies work.

- Material Health: C2C supplies are checked for more than 10,000 dangerous substances. This means that there won’t be any “off-gassing” of harmful fumes, thus the rooms will smell as fresh as a forest.

- Economic Rebirth: Owners can get back a lot of money at the end of a building’s life by selling the “materials” back to the maker if they see buildings as assets instead of liabilities.

- Connection to Place: C2C promotes the use of local, renewable materials, which creates a unique architectural language that celebrates the differences between regions instead of making everything look the same around the world.

The Challenges Ahead: Getting Over the Linear Mindset

There are some problems with the changeover.

- Cost Barriers: The first “circular” design can cost 5–10% more, even though the long-term ROI is higher.

- Supply Chain Complexity: We need a strong infrastructure for “re-manufacturing” discarded materials, which is a field that is just starting to grow.

Final Thoughts: Saving the Future, One Beam at a Time

The time of the “disposable building” is coming to an end. The Circular Economy Act of 2026 is now in full effect. The Cradle-to-Cradle framework is showing the building industry how to give back more than it gets.

By thinking about the “next life” when we create, we are creating a future where our cities are not scars on the environment, but part of its dynamic, breathing rejuvenation.

A Quick FAQ about the C2C Construction Revolution

Q: Is it possible to make historic buildings C2C-ready?

A: Yes, for sure. New buildings are easier to fully “Design for Disassembly,” but adding C2C-certified paints, insulation, and modular partitions to an existing building can make it much more circular.

Q: What will be the most circular material in 2026?

A: Steel is still one of the best “technical nutrients” since it can be recycled over and over again. However, Cross-Laminated Timber (CLT) from certified forests is the best “biological nutrient.”

Q: Does C2C help you reach your Net-Zero goals?

A: Yes. When you reuse materials, you get rid of the huge “embodied carbon” footprint that comes with making new concrete or steel.

For more blogs like this CLICK HERE!!

Reference: