The “concrete jungle” was a sign of human development for a long time, but it came with a high cost. Traditional building has caused around 40% of the world’s CO2 emissions and a lot of resources to run out. But as we approach into 2025, something amazing is happening. We are no longer merely “building greener.” We are now in the age of regenerative architecture, when the materials we use really help the world heal.

This change isn’t only about staying alive; it’s also about doing well. The materials of 2025 are turning our dwellings into living ecosystems that give back more than they take. For example, structures that “breathe” and walls that “heal” themselves.

The Beginning of Living Materials: Mycelium and Bio-Fabrication

The biggest change in 2025 is the switch from “dead” materials like steel and stone to “living” bio-composites. Mycelium, which is the root structure of mushrooms, is at the front of this movement.

Instead of firing bricks in a kiln, architects are instead “growing” them. These fungal bricks are not only very light and biodegradable, but they are also fireproof and provide better thermal insulation. When a mycelium construction is done with its life, it doesn’t go to a landfill; instead, it becomes compost and adds nutrients back to the earth. This cycle shows a deep regard for the natural cycles of the Earth.

Self-Healing Concrete: No More Crumbling Infrastructure

After water, concrete is the second most used material on Earth. Its tendency to crack has always been its biggest problem, which means that repairs are always heavy in carbon. Self-Healing Concrete has gone from the lab to the job site by 2025.

Structures may now fix their own cracks by adding certain microorganisms (like Bacillus) and nutrients to the concrete mix. When water gets into a fissure, the bacteria “wake up,” eat the nutrients, and then excrete limestone, which seals the break from the inside out. This amazing technique makes bridges and buildings last for decades longer, which cuts down on the “embodied carbon” that comes from tearing down and rebuilding.

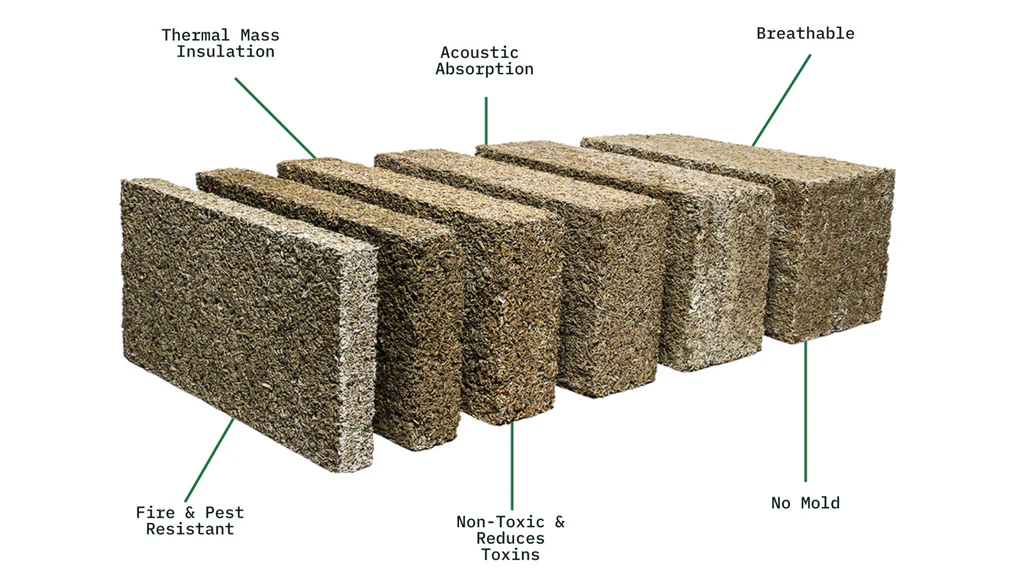

The Rise of Carbon-Negative Alternatives: Ferrock and Hempcrete

The rise of alternatives that are good for the environment, such Ferrock and Hempcrete

For a long time, steel and regular cement have been the major materials used in buildings. But in 2025, Ferrock and Hempcrete will become more popular.

Ferrock is made from recycled things like steel dust and pulverized glass, and it is truly carbon-negative. It absorbs and holds CO2 from the air as it solidifies, turning a greenhouse gas into a useful building material. It is much stronger and more flexible than regular Portland cement, which makes it a great choice for places that are likely to have earthquakes.

Hempcrete is a “breathable” material made from the woody inner fibers of the hemp plant combined with lime. It controls the humidity inside the building organically and stores carbon throughout the life of the building. It gives us a nostalgic link to the land and shows that the plants we nurture may also be the walls that keep us safe.

The “Wood” of the Future: Bamboo and Mass Timber

Cross-Laminated Timber (CLT), which will be available in 2025, is a game-changer for wood, which is an old material. These “super-plywoods” let us create wooden skyscrapers (plyscrapers) that are as safe from fire as steel but store carbon instead of letting it out.

Bamboo has also taken back its title as “green steel” of nature. Bamboo grows up to three feet in a single day, which means it can be harvested far faster than traditional hardwoods. In 2025, bamboo is employed not only for flooring but also as the main structural scaffolding and load-bearing columns in luxury eco-villas. This combines high-end looks with exceptional sustainability.

Amazing Insulation: From Aerogels to Sheep’s Wool

The envelope of the building is where energy efficiency begins. Materials that are both high-performing and “human-centric” are taking the place of traditional fiberglass insulation.

Aerogels, which are sometimes known as “frozen smoke,” are the lightest solids in the world. In 2025, windows and wall panels made with aerogel have the best insulation values ever, keeping homes warm with nearly little energy use.

Sheep’s Wool: A nostalgic favorite, wool is being employed in high-end, eco-friendly buildings. It naturally controls humidity, cleans the air within by absorbing dangerous chemicals (VOCs), and may be used over and over again. It makes buildings feel soft and warm in a way that industrial materials can’t.

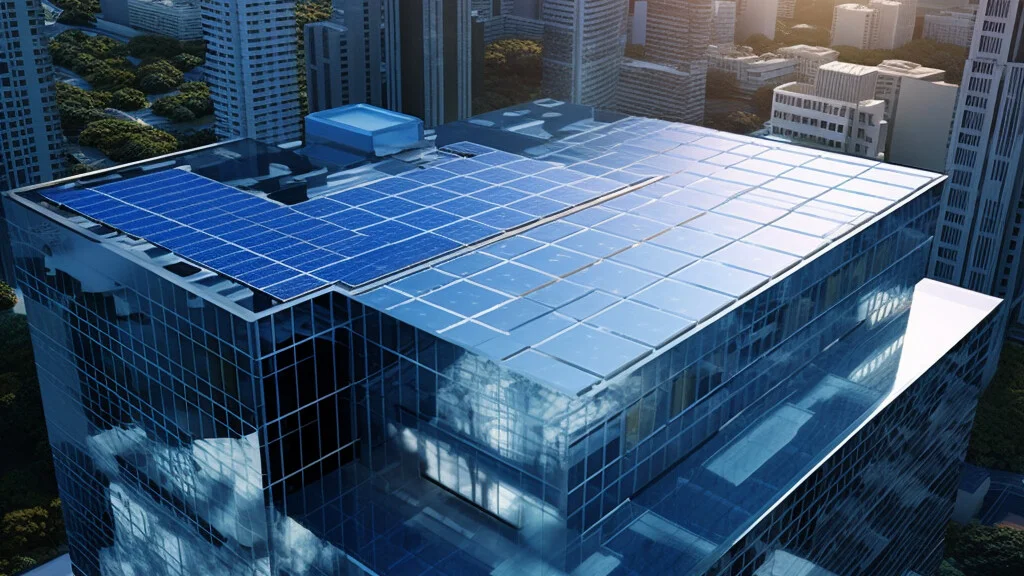

Smart Glass and Solar-Powered Facades

In 2025, the windows of our buildings will no longer just be panes of glass; they will also be energy generators. You may now put transparent solar cells, also called photovoltaic glass, in skyscrapers. This makes the whole outside of the building a vertical power plant.

Also, homeowners may use a smartphone app to change the color of their windows or let AI do it automatically based on where the sun is. This cuts down on “heat gain” in the summer and keeps warmth in the winter, which can save you up to 30% on air conditioning bills. It’s a beautiful mix of caring for the environment and using digital technologies.

The Human Impact: Why Sustainable Materials Matter to You

The evolution of materials is not only good for the environment, but also for your health. Toxic glues, paints, and synthetic finishes can make people sick in traditional buildings. The 2025 suite of eco-materials is based on Biophilic Design, which is the premise that people naturally want to connect with nature.

Studies have shown that living in a house made of natural, non-toxic materials can:

- Lower Stress: Natural materials like wood and hempcrete lower heart rates and cortisol levels.

- Improve Sleep: Better air filtration and “breathable” walls can help you sleep better. On average, people who sleep well score 6% higher.

- Increase Productivity: People who work in “Green-Certified” facilities do far better on cognitive testing and creative problem-solving.

The Truth About Money: Is Green Finally Affordable?

A popular fallacy is that only rich people can “heal the Earth.” The 2025 Market Outlook suggests a different story, even though initial material costs may be 5–10% higher:

- 5% savings on operating costs: The “green premium” usually pays for itself in the first two to three years through lower energy and water bills.

- Asset Appreciation: Right now, sustainable buildings are worth 9% more than regular buildings when they are sold.

- Government Support: By 2025, more than 50 countries had started giving “Green Building Credits,” which provide developers big tax breaks for employing materials that store carbon.

The Future: 3D Printing with Garbage and Earth

As we get closer to the end of the decade, 3D Construction Printing (3DCP) is “printing” homes out of local soil and plastic garbage that has been repurposed. This cuts down on emissions from transportation and lets you make beautiful, organic shapes that look like the curves found in nature. We finish the ultimate cycle of sustainability by building our homes out of the exact ground we walk on.

Conclusion: Building a Legacy for Tomorrow

In 2025, the development of eco-friendly construction materials will be more than just a technological milestone; it will also be a change in the human heart. We are going from being “exploiters” of the land to “stewards” of the Earth.

You aren’t just buying a house when you choose one that is made of self-healing concrete, insulated with sheep’s wool, or powered by solar glass. You’re putting money into a future where our footsteps make the world a better place. It is here, it is highly advanced, and it is stunningly gorgeous.

For more content like this CLICK HERE!!!

Reference:

Top Emerging Building Materials for 2025: Redefining Sustainable Construction