The $31 Billion Silence: Why Communication is Your Most Valuable Tool

In the high-stakes world of American construction, not saying something can be just as deadly as a problem with the structure. As we move into 2025, the data should still be a wake-up call for the industry: approximately 48% of all rework on U.S. projects is due to bad communication and project data that is hard to get to. FMI and Autodesk say that this means the United States loses a shocking $31.3 billion a year in costs that could have been avoided.

You’re not alone if you’ve ever felt “burnout” in the middle of a project because of repeated RFI loops, plans that don’t match, or unhappy subcontractors. But it doesn’t have to be a delusion that “stress-free” is real. You can turn your job site from a messy place into a high-performance machine by learning how to use both technology tools and the psychology of communication.

The “One Source of Truth” Plan

The “information silo” is one of the main reasons why projects in the US fail. This happens when the architect has one set of plans, the general contractor has another, and the subcontractor is working off a screenshot of a text thread from two weeks ago. There is no way to avoid making mistakes when data is broken up.

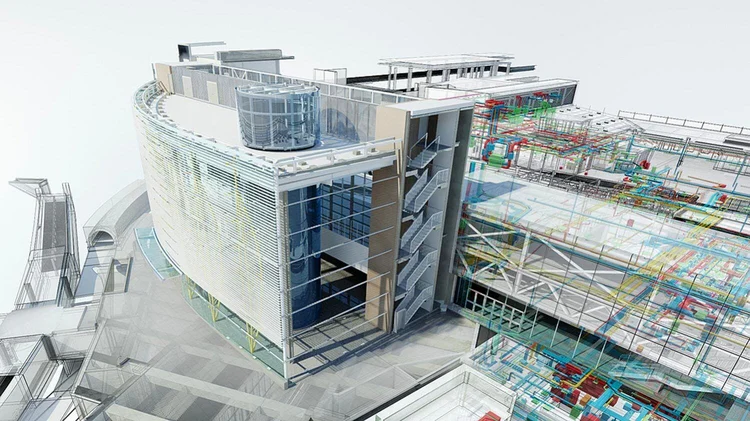

- The Plan: Create a Common Data Environment (CDE). If your company uses Procore, Autodesk Build, or Buildertrend, everyone who works for it must agree to a digital pact: If it’s not in the system, it doesn’t exist.

- Why it works: Having access to the most recent approved drawings in real time cuts down on design-related rework, which is a huge source of project mistakes right now.

- Pro Tip: Put QR codes up in real life on the job site. Field staff can scan a code on a mechanical room door or a structural beam and get the most recent RFI, submittal, or O&M manual for that area right away.

Closing the Gap: The “Trailer vs. Field” Divide

The physical and mental gap between the project trailer and the “boots on the ground” has been a problem in the US construction industry for a long time. Successful leaders are bridging this gap in 2025 by being completely open and using data in context.

In construction, communication isn’t only about sending emails; it’s also about listening and understanding. When a field supervisor thinks that the office doesn’t comprehend the physical limits of the location, they avoid telling them about tiny problems. Those little problems turn into huge change requests over time.

The Plan of Action:

- The 15-Minute Daily Huddle: Don’t let it turn into a marathon. Stand it up. Talk about three things: What happened yesterday? What is the goal for today? What are the problems?

- Make the data more human: Instead of saying “We need the paperwork,” say “We need the safety certification by 5 PM so the crane crew can start on time tomorrow.” Context makes things easier and makes people more likely to follow the rules.

ConTech 3.0: Tech That Works

We are now firmly in the ConTech 3.0 era. “Having an app” isn’t enough anymore. It’s all about how that information moves from one platform to another. According to 75% of construction professionals, there is now a greater demand for quick, data-driven decision-making on the job site to keep up with shorter project timeframes.

To be successful without stress, here are some important tech trends to follow:

- AI-Powered Reporting: New tools can now take voice-to-text notes from a superintendent and turn them into professional daily logs on their own. This cuts down on hours of boring administrative labor and keeps the client up to date.

- Reality Capture: Tools like OpenSpace or Matterport let you take pictures from all angles. The office may check on progress without having to sit in traffic for three hours by “walking” the site digitally.

- Geofencing for Safety: GPS-based automated clock-ins get rid of payroll problems and, more crucially, make sure you know exactly who is on site in case of an emergency.

Overcoming the Language and Talent Barrier

The US construction sector is currently dealing with a double-edged sword: a huge scarcity of workers and a workforce that is very diverse, with about 30% of workers being Hispanic or Latino. 67% of employers say that language barriers make it hard for people to talk to each other, which is a big safety and productivity risk.

The Plan for Inclusion:

- Visual Aids over Text: Use icons, color-coded signs, and 3D BIM diagrams instead of text. A image of a properly installed flashing detail is the same everywhere, but a three-paragraph letter in English is not.

- Bilingual Documentation: Make sure that any important mission statements, safety rules, and toolbox lectures are available in both English and Spanish.

- Respect the Craft: Workers typically leave because they don’t feel connected to their profession. When everyone knows why a project goal is important, they all feel like builders instead of just numbers on a budget.

Managing the “Human Side” of Stakeholders

With loan rates going up and down and the economy slowing down, US project owners are more careful than ever with their money. Your sole shield against lawsuits and disagreements is being open.

Strategic Openness:

- The “No Surprises” Rule: The “No Surprises” Rule says to tell people terrible news just as quickly as good news. If a material delay is anticipated owing to supply chain concerns in the Midwest, communicating it three weeks out allows for scheduling adjustments. Communicating it the day the crew arrives triggers a meltdown.

- Standardized Change Orders: Treat change management as a sacred ritual. Every modification should follow a set path: Request → Pricing → Approval → Implementation. This stops the dreaded “unpaid extra” talk from happening when the job is over.

The Psychological Blueprint: Making a Job Site “Psychologically Safe”

What does psychology have to do with putting concrete down? All of it. The construction industry in the US has one of the highest levels of stress of any industry. A “stress-free” project begins with a workplace where employees aren’t scared to admit when they make a mistake.

If a worker accidently cuts a conduit and is scared of getting yelled at, they will conceal it with drywall. That mistake costs $10,000 to repair two months later. It costs $50 if they feel confident reporting it right away.

- Celebrate “Good Catches”: Reward workers who find possible mistakes or safety risks by celebrating “Good Catches.”

- Stop Playing the Blame Game: Instead of blaming someone for the process failing, look at why it failed.

The “Post-Mortem”: Closing the Loop for Future Profit

Most projects “end” with a punch list and a final check, yet the most successful American businesses employ communication to help them flourish in the future. You can’t get better if you don’t keep track of what you do.

The last step is to hold a formal “Post-Mortem” meeting within 14 days of the project being mostly done. Ask your internal staff and your subcontractors:

- Where did the flow of information stop working during the rough-in phase?

- Was the architect’s reaction time to the RFI long enough?

- What is the one thing we should do or do to make the next job 10% faster?

Conclusion: Communication is Your Best Tool

You wouldn’t think of starting a foundation without a level or a transit, so don’t start a project without a solid plan for how to talk to people. Mastering Building In the US, communication isn’t just about talking more; it’s about making a culture where information is correct, easy to get to, and humanized.

You don’t only cut down on rework when you follow this plan: centralizing your data, bridging the gap between the field and the office, and putting people first. You make a name for yourself. Your reputation for clear, honest, and quick communication is what will really last in an industry based on concrete and steel.

For more content like this CLICK HERE!!!

Reference:

Mastering Construction Communication: Strategies for Success