Concrete and steel are the two main components that make up the world’s big constructions, from tall skyscrapers to huge bridges. For architects, engineers, and project developers, choosing between a concrete frame structure and a steel frame structure is not merely a technical issue; it is a strategic choice that affects the cost, timing, flexibility, and lifespan of the building as a whole.

It’s important to know the pros and cons of each material inside and out, especially because the industry is moving toward faster, stronger, and more ethical building processes. Let’s look at this final structural confrontation and compare the things that really matter.

The Main Fight: Strength and Performance of the Structure

In structural engineering, strength is assessed in two ways: compression (the ability to resist being crushed) and tension (the ability to resist being pulled apart).

Concrete: The King of Compression

Concrete is a composite material that is well-known for being very strong when compressed. When you mix cement, aggregates, and water together, you get a solid block that is great for foundations, columns, and walls that can hold a lot of weight.

- The Problem: Concrete on its own doesn’t have a lot of tensile strength. This is why it is nearly often used with steel reinforcement (rebar), which makes Reinforced Concrete (RC). The steel takes care of the pulling forces, and the concrete takes care of the crushing forces.

- Design Flexibility: One emotive benefit of concrete is that it can be shaped in many ways. It can be poured into complicated shapes and shaped on-site into almost any shape, which is why it is the best choice for big, curved, or architecturally demanding constructions.

Steel: The Titan of Strength

Iron and carbon make up structural steel, which is a strong metal that is light in weight. It is very strong in both compression and tension, which makes it perfect for heavy, complicated loads.

- Weight Advantage: Steel is much lighter than concrete but has the same degree of strength. This is very important for building tall buildings since a lighter structure puts less stress and cost on the foundations.

Steel is quite ductile, which means it can bend and stretch. A steel structure can bend and absorb energy during strong winds or earthquakes, which lets the building change shape a little without falling down. Concrete is more stiff than other materials, hence it is more likely to crack and fail completely under very strong lateral stresses unless it is built to do so.

Cost and Time Efficiency of Construction

When choosing between steel and concrete, the main trade-off is usually between the cost of the materials up front and the pace of construction.

Steel: Quick, Accurate, and Cost-Effective in the Long Run

Steel parts are made off-site in controlled manufacturing circumstances with a lot of accuracy. They are then brought to the construction site and put together quickly, frequently with bolts, like a huge adult-sized building toy.

Speed is Money: This method of building on an assembly line cuts down on the time it takes to build on site by a lot. Less time on site implies fewer labor expenses and a quicker return on investment for the developer.

Cost Nuance: Raw fabricated steel is usually more expensive than raw concrete materials, but the savings from less labor, shorter project time, and lighter foundations can make steel constructions more cost-effective overall, especially for buildings with several floors or long spans.

Concrete: Slow, Hard Work, but Cheap Up Front

Concrete constructions are usually cast-in-place (or cast-in-situ), which means that the formwork (molds) must be built on-site, the concrete must be poured, and then it must be given time to set and cure (which can take up to 28 days to attain full strength).

Weather Sensitivity: The drying process is affected by the weather and adds a lot of time to the job.

Requires a lot of work: This method needs a big, professional on-site workforce for formwork, rebar placement, pouring, and finishing.

Cost Upfront: Sand, gravel, and cement are cheap and easy to find all around the world. This makes concrete the best choice for low-rise and residential construction that doesn’t need to be done quickly.

Fire resistance and durability Resistance and Security

Any construction that works well must have safety and longevity as its main features.

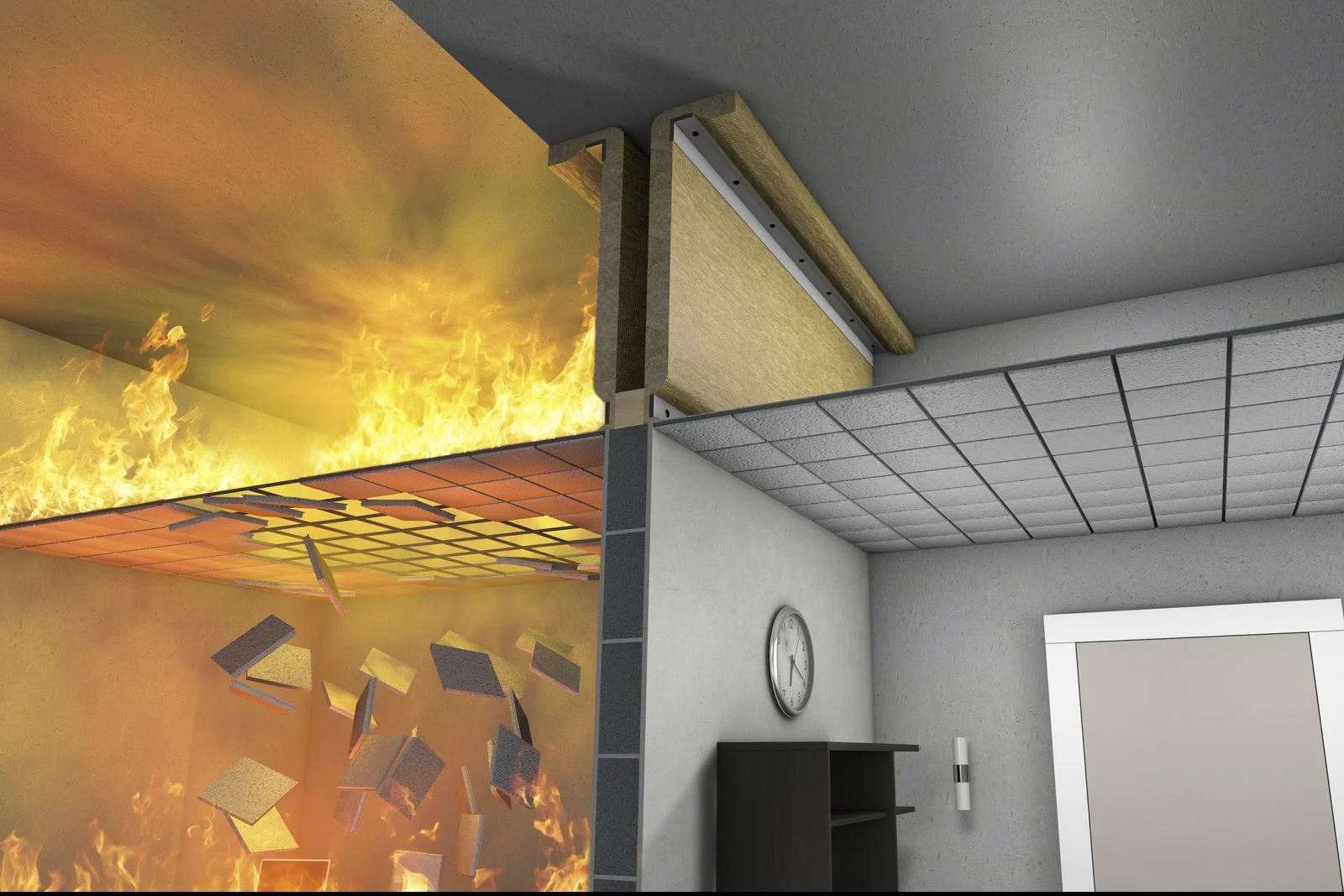

Fire: Concrete’s Natural Defense

Concrete: Concrete does not catch fire. Because of its mass and limited thermal conductivity, it takes a long time to heat up, which makes it naturally fire-resistant and keeps the steel reinforcement from failing at high temperatures for a long time.

Steel: Fire is steel’s biggest vulnerability. Steel loses a lot of its strength and stiffness at temperatures near 500 degrees Celsius (932 degrees Fahrenheit), which might cause the structure to fall apart. So, to meet safety requirements, steel frames need to be covered in expensive fireproofing materials like intumescent paint or concrete/gypsum encasement.

How Long It Lasts and How to Care for It?

Concrete: When mixed and cured correctly, concrete lasts a long time and doesn’t get damaged by water, weather, or bugs. It needs minimal upkeep over its extended life, but if the internal rebar rusts, it might crack and spall.

Steel: Steel is not living and cannot be eaten by termites or rot, however it can rust easily in humid or coastal areas. To make sure it lasts a long time, it needs to be maintained from time to time with things like protective coatings or galvanization.

The Ethical Factor: The Environment and the Amount of Carbon Footprint

The embodied carbon in their materials, or the emissions that come from making them, is something that modern architects have to deal with. The Problem with Concrete: Making cement in the traditional way is one of the biggest industrial sources of CO2 emissions in the world, which means that concrete has a high embodied carbon footprint. But the industry is getting better quickly with low-carbon cements and technology that capture carbon.

Steel’s Benefit: Steel is the most recyclable material in the world. It is possible to recycle structural steel almost completely at the end of a building’s life without losing any quality. This high level of material circularity makes up for a lot of the energy needed to make it in the first place.

Conclusion: The Best Choice for the Project

The “ultimate” comparison shows that neither concrete nor steel is always better. They are both important building blocks that work well in different situations:

| When to Choose… | Concrete Frame Structure | Steel Frame Structure |

| Project Focus | Low-cost, complex shapes, or high thermal mass/fire resistance. | Speed, long open spans, high-rise, or seismic resilience. |

| Key Advantage | High compressive strength and inherent fire resistance. | High strength-to-weight ratio and exceptional construction speed. |

In the next few years, the best projects will probably use hybrid structures that combine a concrete core (for fire safety and stiffness) with a steel perimeter frame (for speed and long spans). This will use the best of both long-lasting materials to meet the ethical and economic needs of modern architecture.

For more blogs like this CLICK HERE!!

Reference:

Concrete Structures vs. Steel Structures: A Comprehensive Comparison – MFG Shop