Introduction: More than just Reduce, Reuse, Recycle

The “take-make-waste” model is what the world economy is based on. This linear model takes limited resources, makes things out of them, and then transforms them into trash and pollution. It is a system that is bad for the economy and the environment.

But a revolution is in the works. The Circular Economy is more than just recycling; it changes the way we think about design. It makes us reconsider everything to make sure that materials are used for as long as feasible.

Three tactics that work together to make this movement stronger are Design for Disassembly (DfD), Circular Minimalism, and Zero-Waste tactics. They all work together to create a plan for an economy that really heals and grows. This post will talk about how combining these three pillars can cut down on waste, cut down on consumption, and create real, long-lasting value.

Source: ecofriendlybliss.com

The Foundational Shift: From Linear to Circular

The linear model fails because it always ends in waste. Things are made to be used and thrown away.

The Ellen MacArthur Foundation says that the Circular Economy is based on three main ideas:

- Get rid of trash and pollution: Don’t even think about trash when you design something.

- Circulate Products and Materials: Reuse, repair, remanufacture, and recycle materials and products to get the most value out of them.

- Regenerate Nature: Don’t only try to do less harm; actively make the environment better.

For designers, this involves asking questions that are very different from what they usually do: How will this thing break? Is it safe for this stuff to go back into the biosphere? Is this the smallest and most important form of the product?

Pillar 1: Designing for Disassembly (DfD)

Design for Disassembly (DfD) is probably the most important technological strategy in the circular toolkit. Designing products, buildings, and systems with the goal of making them easy and cheap to take apart at the end of their useful life is what DfD means.

This isn’t simply to make recycling easier; it’s also to make it possible to recover, maintain, and repair valuable materials. A product that is meant to be taken apart is not garbage; it is a resource that is waiting for its new life.

Important DfD Strategies:

- Mechanical Over Chemical: The most important guideline of DfD is to use mechanical fasteners like screws, bolts, clips, and snaps instead of chemical ones like adhesives, glues, and welds. Chemical bonding make it hard to separate materials, which can turn a valuable part into low-grade garbage.

- Modularity and Standardization: Products that are made with parts that can be easily swapped out and standardized parts last a lot longer. You only have to replace the portion that breaks, not the whole thing. Modular furniture systems and gadgets that are easy to upgrade are two great examples of this principle in action.

- Connections that are easy to find and use: You should be able to see and reach connections with common tools. This cuts down on the time, money, and specialist labor needed for repairs or demolition.

- Material Passports: Material Passports are digital or physical records that are attached to a product or building that list all of its parts and materials, where they are, and how to safely take them apart. This gives future recyclers or remanufacturers the exact information they need to get materials back quickly.

Companies that use DfD not only cut down on waste, but they also keep valuable materials, which gives them a financial reason to get things back and “close the loop.”

Design for Disassembly Architecture. Source: ar.inspiredpencil.com

The Power of Circular Minimalism is Pillar 2

While DfD looks at the technological side of things, Circular Minimalism looks at the philosophical side of consumerism and beauty. It’s the belief that less can be more, especially when that “less” is made to last as long as possible and have as little effect as possible.

In this case, minimalism isn’t simply a style; it’s also a way to be more environmentally friendly.

Timeless Design and Emotional Durability

The product that lasts the longest is the most sustainable. Longevity isn’t only about physical strength; it’s also about mental strength. A minimalist design, with clean lines, a focus on function, and a look that never goes out of style, stands up to short-lived trends.

When a product is emotionally durable, the user is less inclined to throw it away for the latest trend. This slows down the cycle of buying and throwing away things by a lot. Think of furniture or equipment that are well-made and meant to last a lifetime.

From Having to Getting

Circular Minimalism also causes a big change in how businesses work. Companies are migrating away from selling a product and giving the consumer ownership (and accountability for waste) to Product-as-a-Service (PaaS) models.

In a PaaS model, the corporation still owns the product, such an office lighting system or a collection of professional tools, but the customer rents its use. The company is responsible for the product’s full lifecycle, so they have a strong financial incentive to make it last, be easy to take apart, and be easy to fix up. This is what minimalism is all about: the user receives the function they need without the mess or waste of owning something for a long time.

CNAD National Art, Crafts and Design Center/ Ramos Castellano Arquitectos. Image: Sergio Pirrone

Pillar 3: Start with Zero-Waste Strategies

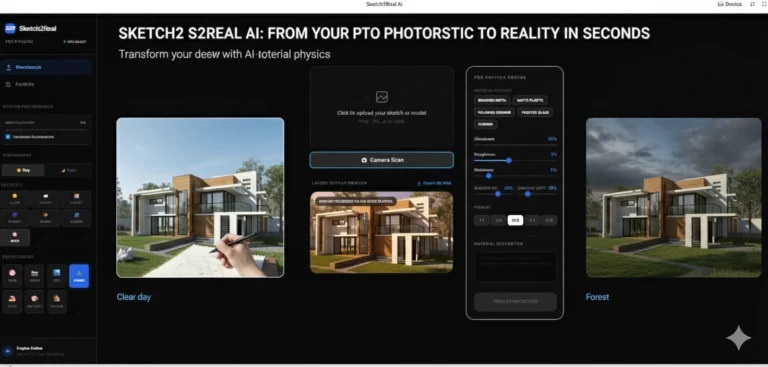

While DfD makes it easier to throw things away after they’ve been used, and Minimalism cuts down on consumption, Zero-Waste Strategies focus on upstream innovation—getting rid of waste before it even has a chance to emerge.

This design philosophy puts the health of materials first. Every part must be a technical nutrient (a safe material that can be used over and over again in industrial loops) or a biological nutrient (a material that can break down safely and bring the soil back to life).

Making The Best Choices About Materials and Production

Choosing the right materials is the first step in making a design that is genuinely zero waste.

- Prioritize Regenerative Sourcing: Designers should use materials that not only can be recycled but also help the environment while they are being made or grown. Plastics generated from collected carbon emissions and farming products that improve soil health are two examples.

- Closed-Loop Manufacturing: The purpose of production should be to make no waste. This means making things with great care, utilizing digital tools to improve cutting patterns, and setting up processes to take back any production off-cuts or defective batches.

- Get rid of packaging waste: Packaging is one of the worst examples of linear design. Zero-waste plans call for packaging that can be reused, composted, or thrown away totally. This is especially important for e-commerce and fast-moving consumer items.

Designers are basically saying that every input will have a safe output, either back to nature or back to the factory, by committing to a zero-waste plan.

Source: prefabaus.org.au

Conclusion: Building the Future, Not the Trash Heap

Circular Economy Design, Design for Disassembly, and Circular Minimalism work well together to create a strong and complete way to move forward.

It’s a world where items are made to be useful for their whole life, not just when you buy them. It is a way of thinking that replaces the fear of waste with the creativity of renewal.

Engineers, designers, business strategists, and customers all need to work together for this change to happen. As designers, we have the power to change our industrial system from one that hurts people to one that heals them. It’s not about doing less harm in the future; it’s about designing for good. Use the ideas of disassembly, minimalism, and zero waste to help you come up with your next big idea.

References:

Minimalism and Zero-Waste: Simplifying Your Life for Sustainability

Circular Economy in Product Design: Creating Zero-Waste Products – Two Green Leaves

For more blogs like this CLICK HERE!!